The biennial ACCADUEO H2O exhibition has been the reference event for the Italian water sector for the past 30 years. Its 16th edition was held in Bologna in October 11th-13th and featured a busy schedule of events and conferences alongside two halls hosting hundreds of international exhibitors. Among them was Easy Hydro, who shared a stand with our partner Tecnidro.

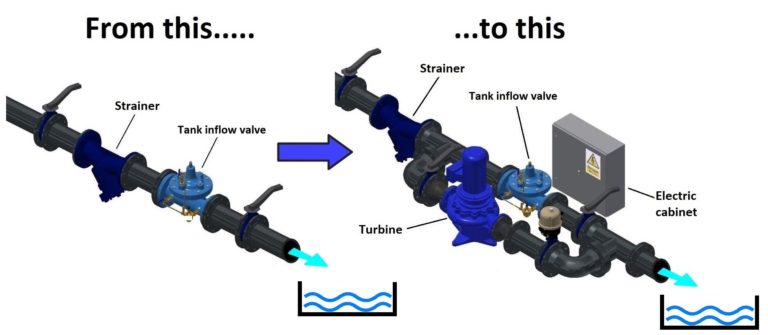

This was the perfect opportunity to present a full-scale prototype of our hydro energy recovery solution for pressurized water networks. Instead of just dissipating the excess available pressure via throttling valves or tank inflow valves, the adoption of an Easy Hydro system allows the network operator to generate some valuable green electricity as a byproduct.

A big thank you to Tecnidro, SAER Elettropompe, to the organizers of the event and above all to the many who stopped by our stand during the three days! Stay tuned for the upcoming Easy Hydro events.